Single Container Water Hammer Tester

Single Container Water Hammer Tester

In order to supply safe glass containers to the market, Toyo Glass runs a wide variety of strength tests. This Single Container Water Hammer Tester makes it possible to measure water hammer strength comfortably and accurately.

Features

The test can be conducted with a single glass bottle without a carton.

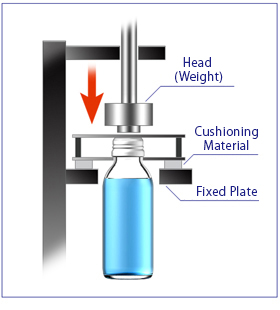

Single Container Water Hammer Tester measures water hammer strength of a glass bottle by dangling a bottle at its neck and then dropping a weight on the top of the filled and capped bottle from above to generate Water Hammer Phenomenon. As no carton is required, the test can be conducted using only a single glass bottle, and due to that, the strength of a glass bottle itself can be examined.

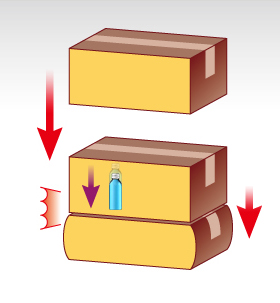

What is Water Hammer Phenomenon ?

During distribution of filled glass bottles packed in a carton case, when a carton falls from above of double-stacked cartons, the bottom carton gets crushed. The bottles inside a carton on the crushed carton drop down corresponding to the crushed amount of the carton. However, the filling content remains at the same position for a short period due to the inertia. After a small fraction of time lag, the content starts dropping, and gives an impact on the bottom heel of the glass bottles, which can cause bottle breakage.

This is usually called the “Water Hammer Phenomenon”. Also, in rare cases, a partially cracked by this Water Hammer Phenomenon but unbroken glass bottle whose inside is negative-pressured is delivered to a consumer.

When the bottle is opened by the consumer, the negative pressure inside the bottle is released, and the filling content pushes the bottle out from inside. The crack on the inside surface of the bottom heel part is promoted, and finally leads to breakage of the glass bottle. This may dirty the consumer’s clothing by the content or hurt the consumer by the shards of glass.

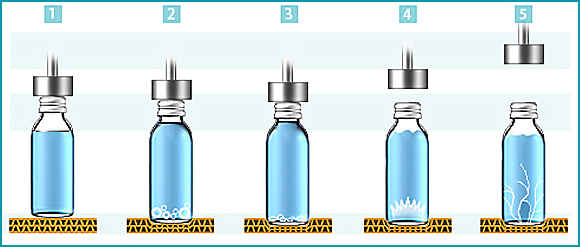

Process of glass bottle breakage caused by Water Hammer Phenomenon

1 A filled glass bottle rapidly falls down.

2 -1 The liquid content remains in the same position inside the bottle by its inertia force.

2 -2 The volume of the head space above the filling point is reduced.

2 -3 To compensate the reduced volume of the head space, cavities are generated between the liquid content and the bottle bottom.

3 When a cavity collapses, it engulfs its surrounding water and a microjet arises, and then tiny cracks (impact traces) are formed on the heel and bottom of a glass bottle.

4 The liquid content falls down due to the high pressure in the head space and gives a strong impact on the bottle bottom.

5 Stress is concentrated on the inside surface of the bottle heel and the glass bottle starts to break from the tiny cracks on the bottle heel.

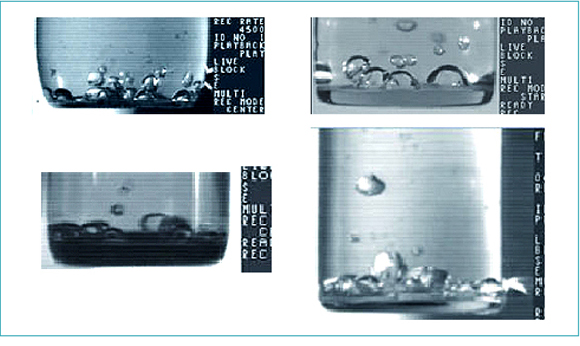

Images of actually-occurred cavites

The actual generation time of cavities is approximately 0.001 seconds.

They can not be seen with the naked eye.

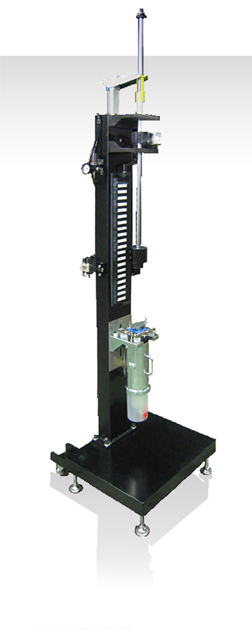

Overview of Testing Device

Conceptual Diagram of Testing Device

Since no undesired reaction force occurs by hanging a glass bottle in the air, glass bottle falls exactly vertically.

Usage of Single Container Water Hammer Tester

There are two types of the tester. One type moves the head(weight) automatically with an air cylinder, and the other type, shown on the below demo, is a type which the head(weight) is moved by hand. Both types are available at Toyo Glass.

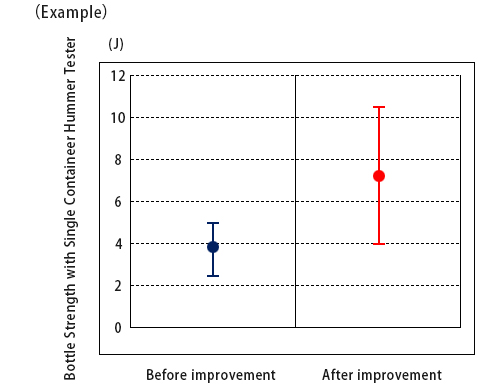

Strength test results of the tester

The benefit of Single Water Hammer Tester is that it can quantify the Water Hammer strength, which makes it possible to compare the strengths between products before design improvement and after design improvement.