Shear Blade

Shear Blade

“Toyo Shear Blades” have been used by glass container/tableware manufacturers in Japan for a long time, and also they’ve been exported to and highly appreciated by a lot of glass plants in Asian countries.

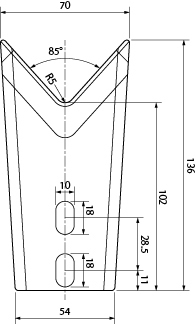

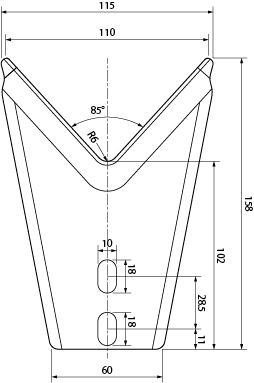

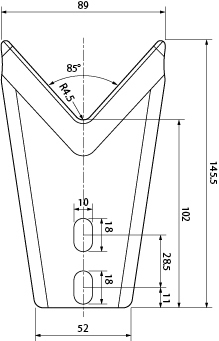

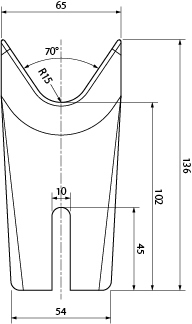

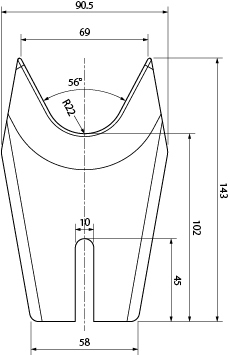

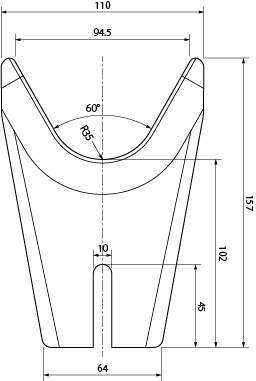

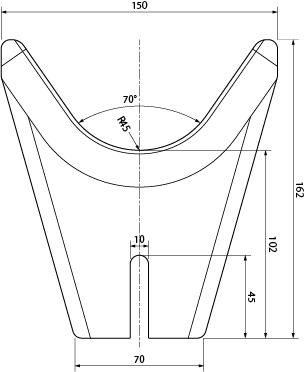

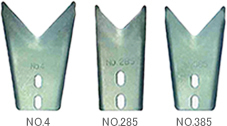

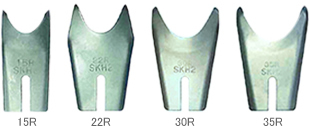

Wide variation in size and shape (V series ,U series)

| Description | |

| V series | Standard For high-speed production line |

| U series | Long life For large bottle & tableware production |

Advantages confirmed in Bottle Producation at Toyo Glass Plants (Japan)

●Reduction of product defects like Shear Mark and Split Sealing Surface

The Japanese market is recognized for the quality, and strongly requires glass manufacturers to eliminate such defects arising from gob cutting as Shear Mark, Split Finish and Blistered Finish.

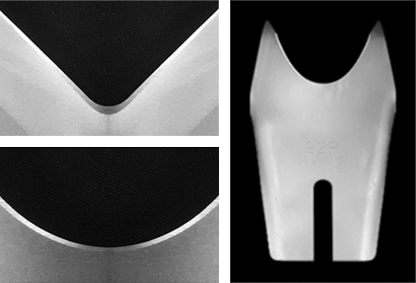

The “Toyo Shear Blade” has helped Toyo Glass and other Japanese manufacturers to significantly reduce Shear Mark, Split Finish and Blistered Finish by its special cutting edge finish-ground by manual.

If Shear Streaks (aggregate of tiny blisters caused by shear blade slipping) are found on your product, “U series” blades is recommended. The curved cutting edge of the U blade enables to squeeze cylinder-shaped glass fallen from a spout along its outside edge and decrease Shear Streaks.

●High wear resistance, Long life and Less downtime

Thanks to the material with the appropriate toughness and the special shape of cutting edge finish-ground by manual, it is possible to avoid over-tension of blades and reduce the rate of blade’s wear. Such a long-life blade having high wear resistance makes it possible to decrease downtime for blade’s change and tension adjustment.

Wide variation in size and shape (V series ,U series)